Before we get into the logistics of the ICA’s most recent webinar, can we just say for a second: what a great title for a webinar! Jason Sutton, executive logistics chef (aka Tetris master) of the Denver-based Footer’s Catering, explains how foolproof warehouse organization and processes lead to smoother events.

Registration for Art of Catering Food is now open! Click here and be the first to register!

The warehouse team at Footer’s Catering, who are responsible for 650 deliveries a year, make use of seven vehicles that they’ve outfitted to match their needs. For example, lift gates have been added to three of their trucks. Much of a company’s success, they’ve realized, has a lot to do with the long-term planning around a fleet and what your company demands.

Footers Catering has a fleet of seven vehicles that are responsible for 650 deliveries each year. Photo courtesy of Footers Catering.

Certified drivers

Footer’s Catering & Events developed their own certification program for their truck drivers to ensure both safety and legitimacy. Driving a truck through Colorado, after all, is no joke. The team developed SOPS, a training checklist, a 30-minute tutorial and a 30- to 45-minute driving test with the operations manager for program trainees. Once the driver is certified and on group insurance, they are then provided with a pay bump, which adds an incentive to becoming certified.

Organizing the warehouse

The Footer’s Catering warehouse makes up 2,300 square feet total and is divided between two teams: production and design. Production is responsible for pulling everything for events, while design helps decide the exact decor, look and feel of the event. Both teams are dedicated to packing, unpacking and organizing trucks before events. Their rule of thumb is to prepack all trucks with equipment and dry materials at least a day before an event.

“When we got into this building, we had to keep finding space and reorganizing. The size of our warehouse works because it’s big but not so big that we’re holding onto stuff that we used for events three or four years ago that will maybe sell again,” Sutton says. “We make a point of purging and making room for new stuff.”

Packlists

For packlists, the warehouse team uses Total Party Planner, which allows them to pull predetermined inventory items. When the sales team builds packlists for which items need to be sent, the program automatically tells them if they are overbooked in selling an item. The warehouse team gets this information a week in advance of an event, which gives them time to double check if they have everything they need.

Systems and labeling

Sutton and the warehouse team use a highlighting system on their packlists, which allows everyone to see who is responsible for packing each truck. They’ve also numbered and labeled individual items by rows in their warehouse.

“It keeps everything super organized, and if someone needs to run back on a Saturday, they can go to the exact row and easily find where the item is located,” Sutton says. “This organization helps us understand where all our pieces go. Every piece has a home.”

Pack the truck with the big stuff first

Sutton’s warehouse team prefers to get their Tetris pieces together before placing them onto the truck. The first to go onto the truck is the cooking equipment—convection ovens, 6-foot grills, 3-foot grills, fryers, candy burners and portable burners. They have two ovens in 3-4 of their trucks now.

Pro tips: Order ovens that are set to liquid propane burners; Keep one hotbox on the truck.

Standard items

The “standard items,” as Sutton puts it, come next. This includes gloves, propane, trash bags, plastic wrap, foil, all the way down to checking fluids in the truck.

Pro tips: Make sure headlights work well! Plastic wrap and foil boxes come in handy. The Footer’s warehouse team retrofitted their trucks with bars that hang on the inside of the trucks.

Then come the next line of essentials—emergency items, cleaning kits and miscellaneous backup items a lead chef might need. The Footer’s warehouse team has these items separated into different colored bins.

Red bin = emergency kit

Heat lamp bulbs, an extra roll of duct tape and an electrical splitter. All 9-11 items go in the red bin!

Green bin = cleaning supplies

Sanitizers, sanitizer tablets, sanding bucket, spray bottle and towels

Yellow bin = lead chef

When they were prioritizing what a lead chef would need on a truck, the team didn’t always pack the right utensils, tongs, spatulas or squeeze bottles. The yellow bin has that one simple thing that might make a chef’s life better on site.

The inside of one of the delivery trucks. Photo courtesy of Footers Catering.

Organizing a truck

Organizing a truck is key to an event’s success. Here are some of Sutton’s go-to pro tips.

- Heavy stuff in the back. They have two ovens in the back and grills on the right hand side. This helps with balance.

- Load bars on top; rachet straps hold everything together. Their team installed an e-track on the wall. Safety is important!

- Everything should be in a vessel.

- Black totes are a great resource. Stack accordingly.

- Organize like items together.

- Fill in any gaps with smaller items for proper space utilization

- Use milk crates for fragile items like platters, urns and plates.

- Wrap plates in plastic and stack in crates. A good go-to number is 25 per crate.

- Ice wrap covers are life-savers!

- Bread racks are great for random stacking and keep things safe and secure.

- Always remember to leave floor room for your chefs!

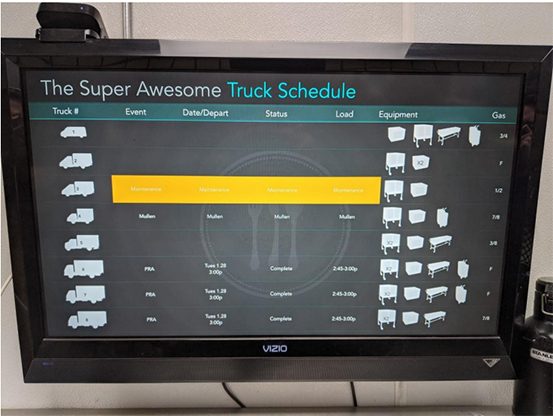

The truck schedule outlines what’s going into each truck, and when. Photo courtesy of Footers Catering.

“Super awesome truck schedule”

Having a dependable warehouse schedule also helps with a smooth production flow.

“Our schedule tells us what’s going onto every truck, who the chef is and what time it’s departing. This helps us connect one side of the brain to the other,” Sutton said.

Keeping it organized once you’re at event

Each event is packed twice, remember. If you’re going to pack it again, you might as well keep your truck tight, Sutton says.

“Try to have the same chef that unpacks the truck at the events repack it at the end of the night,” he says.

Pro tips:

- Lead chefs should also stage their load process before packing.

- Lighting on site is important and makes your team feel safe.

- Footer’s employs a sticker system to help determine items that are broken: clean sticker and broken sticker. Broken stuff goes back to the warehouse manager so he doesn’t have to count every individual piece.

Ultimately, all of the tools and systems the Footer’s warehouse team has in place are supposed to make everyone’s lives easier and make them feel confident in the events they put on together.

“We have enough checks and balances in place that we feel more confident and trusting in our production team’s ability to really see the whole field on inventory,” Sutton says. “We trust our processes and procedures and our team.”

The ICA releases more webinars like this every month. Click here for recent webinars, and be sure to stay tuned for upcoming ones.

Footers Catering & Events is a proud member of the ICA. For more information, visit internationalcaterers.org.